Government was warned UK faced becoming a ‘dumping ground’ for combustible construction products

The government was warned in the early 2000s that the UK risked becoming a “dumping ground” for inferior construction products if tougher European fire standards were not implemented, but did not transition to them amid pressure from industry lobbyists.

The Grenfell Tower Inquiry today saw documents from meetings in 2002 and 2003 which showed officials discussing plans to harmonise the UK’s building guidance with standards being developed in Europe.

This would have meant dispensing with a national British standard called ‘Class 0’ in favour of the new Euroclass standards.

But despite warnings that the country risked becoming a “dumping ground” for lower-quality products, the government allowed guidance to remain in a ‘transition phase’ where both standards applied for 16 years until it was finally amended in 2018 – a year after the Grenfell Tower fire.

Documents from the time showed various industry groups lobbying government against the change to European standards, fearing that it would impact their ability to sell in the UK market.

Notes of an April 2002 meeting between government officials and industry figures said the UK was one of only five EU member states not to have a requirement for ‘CE’ marking of construction products, as it relied instead on the British Standards.

CE marking indicates that products meet applicable standards to be traded across the European Economic Area.

“Members expressed concern that, if the UK were to continue by not making CE marking mandatory, it would become a ‘dumping ground’ for inferior products that could not be sold in other member states,” the notes said.

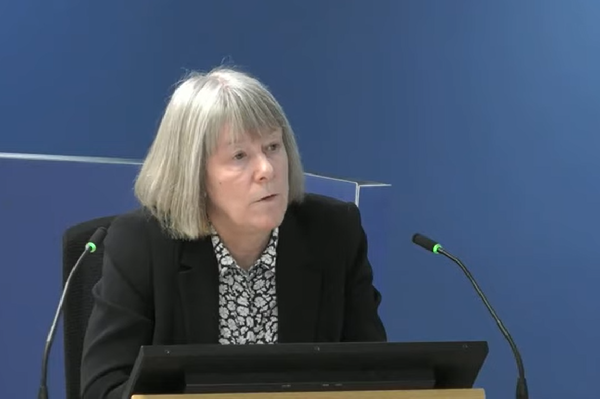

“Was it the case that the UK was a dumping ground for inferior products?” asked lead counsel to the inquiry Richard Millett QC.

“No I don’t believe that was the case,” replied Dr Debbie Smith, former managing director of the Building Research Establishment (BRE), who attended the meeting.

The inquiry has previously heard that Arconic, the French company which sold the violently combustible aluminium composite material (ACM) cladding for use on Grenfell Tower, viewed England as a ‘market’ for the highly combustible panels because it had failed to adopt the higher standards in use across much of the rest of Europe.

“What about a French manufacturer of cladding panels, for example, that couldn’t sell its product in a country which required [higher European standards], it could come here… get a Class 0 and enter the UK market?” asked Mr Millett today.

Dr Smith said that she had believed the British Standards would soon be withdrawn in favour of the European classifications.

Further documents suggested the transition phase to the European standards would start in 2002 and run for three years, during which time both national Class 0 and the Euroclass B rating would be accepted.

After this, new products entering the market would be required to meet Euroclass B and eventually this standard would be required for anything used on a tall building, with the British standard withdrawn.

“Can we agree that the transition plan as stated here was never implemented?” asked Mr Millett.

“It wasn’t introduced in the way laid out here,” replied Dr Smith.

“Do you know why it was abandoned?” asked Mr Millett.

“No,” replied Dr Smith, explaining that this would have been a decision for the government.

The inquiry has already heard extensive evidence that the government and BRE knew by this point that products with a Class 0 rating could pose a substantial risk in a fire.

This included testing carried out in 2001, which showed a Class 0-rated ACM panel similar to the product later used on Grenfell Tower failing a large-scale test in devastating fashion.

“Was any consideration given to the risks to life presented by leaving Class 0 in the [guidance] in this way?” asked Mr Millett.

“Not at that time, I don’t believe so, no,” replied Dr Smith.

The inquiry also saw an email from a lobbying group representing the foam insulation industry from 2002 which noted that while its members’ products could achieve Class 0, they would be ranked ‘C’ or ‘D’ under European standards – below the ‘B’ grade which was to be required in the UK under the transition plan.

The email warned that products could be “prevented from continuing” on the market as a result and said the move to European standards therefore “should not happen”.

A representative for British Steel also argued that a plastic-faced product would generally only achieve a European Class C, despite meeting the Class 0 requirement under British Standards.

The inquiry saw a pamphlet produced by giant insulation manufacturer Kingspan in May 2003 which discussed the impending changes and claimed the new standards would not be implemented for “five to 10 years”.

“Furthermore HM government has stated that it will not implement the new Euroclass system until industry is ready for it,” the document said.

Dr Smith said she was surprised by the document and could not explain where Kingspan had got this impression from.

Dropping the Class 0 standard from official guidance was also recommended by a parliamentary select committee that was investigating the risks from cladding fires in 1999.

It said all cladding systems should have been required to be “entirely non-combustible” or subjected to a large-scale test being developed by the BRE.

But guidance on this testing produced in 2003 by the BRE said the Class 0 standard would in fact be retained, with the large-scale test to be introduced as an alternative route to compliance.

“Does it follow that by 2003 a decision had been taken not to follow the select committee recommendation?” asked Mr Millett.

“I don’t know,” replied Ms Smith.

Dr Smith was shown a letter – previously released by the inquiry – which showed cladding industry group the Centre for Window and Cladding Technology arguing against the introduction of the full-scale test as the only means to compliance.

The letter said that it was concerned the test could lead to “the abandonment” of the use of rainscreen cladding systems, warning that “if this occurs there could be economic consequences for the building industry and the UK as a whole”.

In the margins, Dr Smith had annotated a note which suggested amending the test methodology to make clear that fire barriers could “improve performance”.

“Was this suggestion a sop to industry?” asked Mr Millett. “It’s an encouragement isn’t it, that if you don’t pass, fire barriers might help?”

“Well you should be incorporating fire barriers anyway,” said Dr Smith.

Since the Grenfell Tower fire in June 2017, the government has claimed that Class 0 cladding should not have been used in England despite the ongoing inclusion of the standard in official guidance.

This is due to the introduction of a passage placing tougher restrictions on what was described as “filler material” in 2006.

The government has claimed that this wording meant the combustible core of an ACM panel was banned, although this has been strongly disputed by industry figures and some inquiry experts.

Asked about this today, Dr Smith claimed the guidance was “clear” that all external wall materials should be of limited combustibility.

But taken through the guidance by Mr Millett, she quickly revised her view to say that external surfaces of walls could in fact still meet the lower standard of Class 0.

The inquiry continues with further evidence from Dr Smith tomorrow.

Sign up for our weekly Grenfell Inquiry newsletter

Each week we send out a newsletter rounding up the key news from the Grenfell Inquiry, along with the headlines from the week

Already have an account? Click here to manage your newsletters