Designers and contractors knew Grenfell cladding system would fail in a fire, inquiry hears

The contractors, architects and fire safety consultants working on the Grenfell Tower refurbishment exchanged emails acknowledging that the new cladding system would fail in a fire, with one writing “as we all know, the [aluminium composite material] will be gone rather quickly” in 2015, the inquiry heard today.

A chain of emails sent between main contractors Rydon, specialist cladding contractor Harley Facades, fire engineers Exova Warrington and architects Studio E was read out to the hearing today.

The emails discuss the need to install strong fire barriers into the system but conclude that doing so was unnecessary as the cladding would be destroyed by a fire regardless of any barriers.

The first email, dated 27 March 2015, was sent by a Harley employee Daniel Anketell-Jones to Ray Bailey, the sole director of the company.

It reads: “There is no point in ‘fire stopping’, as we all know; the ACM will be gone rather quickly in a fire! The whole point [of barriers] is to stop ‘unseen’ fire spreading in the cavity.”

A few days later Neil Crawford, an architect working on the project with Studio E, emailed Terrence Ashton, the fire engineer who prepared the fire safety strategy for the building.

Panels of Aluminium Composite Material (ACM) cladding are commonly used to insulate buildings. They have become controversial since it emerged that Grenfell Tower was clad in the material.

They are made up of two thin sheets of aluminium, with a lightweight core that can be made from various materials. The cladding on Grenfell Tower had a polyethelene core. Updated government advice published today states that aluminium composite material (ACM) cladding of this type should not be used on buildings of any height.

The panels are generally added as part of an insulating system including foam attached to the building behind them. To provide proper insulation, installers leave a cavity between the panels and the foam, and it is in this void that fire safety issues can arise.

In order to preserve the cavity but also prevent it from becoming a deadly chimney, fire breaks are generally installed at regular intervals. These do not block the cavity entirely, but are designed to expand when they detect fire and fill.

Mr Ashton wrote: “It is difficult to see how a fire-stop would stay in place in the event of a fire where external flaming occurred as this would cause the zinc cladding to fail.”

Another Exova employee, identified as Mr Pearson, replied to say: “If significant flames are ejected from the windows, this would lead to failure of the cladding system, with the external surface falling away and exposing the cavity, eliminating the potential for unseen fire spread.”

This email was then forwarded to Simon Lawrence, contracts manager at Rydon, explaining that as a result nobody thought the fire barriers were necessary. “Excellent. That looks positive,” he replied.

The emails were read out by Craig Orr QC, the barrister representing insulation manufacturer Celotex, to rebut claims made in yesterday’s hearing that the designers and contractors were not aware that the products they were using were dangerous.

He said: “Each of Studio E, Exova and Rydon was openly acknowledging that the cladding would fail in the event of a fire with external flaming. That’s tragically what happened on the night of June 14 2017.

“This email exchange shows that risk, which eventuated on that night, was expressly foreseen by the designers, contractors and fire safety consultants responsible for the Grenfell Tower refurbishment.”

Mr Orr also set out Celotex’s argument that it was not responsible for the design and specification of the cladding system, as its only role was to supply the insulation via a third party.

He said that a test carried out in May 2014 and since withdrawn for inconsistencies, which subsequently saw Celotex’s insulation advertised as “acceptable for use on buildings above 18m”, was not relevant as the insulation should have been used only in the system tested. It was installed on Grenfell with far more combustible cladding.

The first section of the lengthy inquiry is investigating the decision to refurbish the tower and specify the particular materials for use in the cladding system. This system has already been identified as the “primary cause” of the rapid fire spread during the blaze that killed 72 people in June 2017.

Earlier, the inquiry had heard from Michael Douglas QC, who opened Exova’s case by explaining that the fire engineers were not asked to give an opinion on the cladding system, a revelation first made by Inside Housing when it obtained their report last year.

He set out more detail about the decision by the designers and contractors to move away from an original plan to clad the tower in a fire-resistant zinc material, which he said related to cost pressures.

The project was experiencing financial difficulties in 2013, he claimed, at which time CEP – the firm that fabricated the panels – approached Kensington and Chelsea Tenant Management Organisation (KCTMO) with the suggestion that cost could be saved by switching the cladding panels.

When Rydon was appointed on a design and build basis it “immediately” began discussions about changing the cladding panels for a cheaper option with KCTMO and its consultants Artelia, Mr Douglas claimed. He said that Exova was excluded from these discussions.

Mr Douglas claimed that senior figures at Rydon said they preferred not to use fire engineers for their projects, and only wanted advice from Exova if it was “free”.

He was followed by Stephen Hockman QC, counsel for Arconic, the manufacturer of the panels, who claimed that compliance with the regulations is not a matter for the firm and instead lies with the designers and contractors who worked on the project.

Yesterday, the inquiry was read internal Arconic emails that appeared to show an awareness that their product was “dangerous” and performed below its advertised standard of Euroclass B – especially when cut into cassette form.

Further emails from Arconic were disclosed online today. They show that the firm claimed it had specific knowledge of how and where its cladding materials were being used.

Commenting on reports of a fire involving ACM in May 2013, Deborah French, UK sales manager at Arconic, wrote: “We… can control and understand what core is being used in all projects due to the controlled supply route we have.”

The inquiry continues tomorrow with opening statements from a variety of parties including KCTMO and the council.

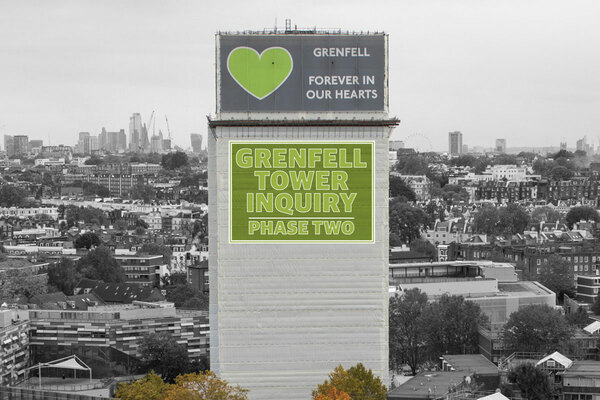

Grenfell Tower Inquiry: phase two timeline

Sir Martin Moore-Bick, the retired judge who chairs the inquiry (picture: Grenfell Tower Inquiry)

The inquiry will be spread across eight modules, with the below timeline set out at the start of the inquiry:

Module one: 27 January to April 2020

Module one will examine the role, acts and omissions of the professionals involved in the refurbishment of the tower from 2012 to its sign-off on 20 July 2016.

Module two: 4 May to mid-June 2020

This section will examine the testing, classification, certification and marketing of key products used in the external wall, particularly the Reynobond PE 55 cladding panels and the polyisocyanurate insulation made by Celotex.

Module three: June to early October 2020

This will involve three topics: first, the complaints made by residents, particularly those relating to fire safety and the quality of the workmanship; second, the compliance with the requirements of the Regulatory Reform Order 2005 by the council, Kensington and Chelsea Tenant Management Organisation and the London Fire Brigade; and finally, active and passive safety measures in the tower. Closing statements for all the first three modules will then follow.

Module four: mid-October to mid-November 2020

This module will assess the performance of local and national government in the immediate aftermath of the fire.

Module five: mid-November 2020 to mid-February 2021

The firefighting operation will be reviewed in more detail in this section, including an analysis of training and the suitability of equipment.

Module six: February 2021 to May 2021

This module will turn the lens on central government, with a focus on the responses to previous incidents and

reports, coroners’ recommendations and things of that nature – including in respect of the building regulations and associated guidance, as well as fires and firefighting.

Module seven: May 2021

One week has been set aside for an assessment of the remaining expert evidence.

Module eight: timetable to be announced

This will assess any remaining evidence, including an attempt to establish how each of the deceased met their deaths. The bereaved and survivors have been invited to make submissions about other matters, which should be considered in this module.

Grenfell Tower Inquiry phase two previews

Picture: Getty

Inside Housing published a series of preview articles ahead of the start of Phase Two of the Grenfell Tower Inquiry on Monday 27 January. You can read them here:

What was known in central government about cladding?

What did officials know about the dangers of fire from combustible cladding, and did they act on the warnings?

Click here to read the full story

The testing and certification of materials

What tests and certificates existed for the materials used in the cladding system on Grenfell Tower, and was the system that provided them fit for purpose?

Click here to read the full story

The decision to install the cladding

Who decided to install polyethylene-cored ACM cladding on Grenfell Tower and why?

Click here to read the full story

The fire doors and windows

What went wrong with the fire doors and window installed at the tower?

Click here to read the full story

The warnings of the local community

What did residents say before the fire and why were they ignored?

Click here to read the full story

Over the course of the inquiry, Inside Housing will publish regular news updates on its progress and a weekly round-up of the key evidence and its significance for the social housing sector every Friday afternoon.