Widely used HPL cladding system dramatically fails official fire test

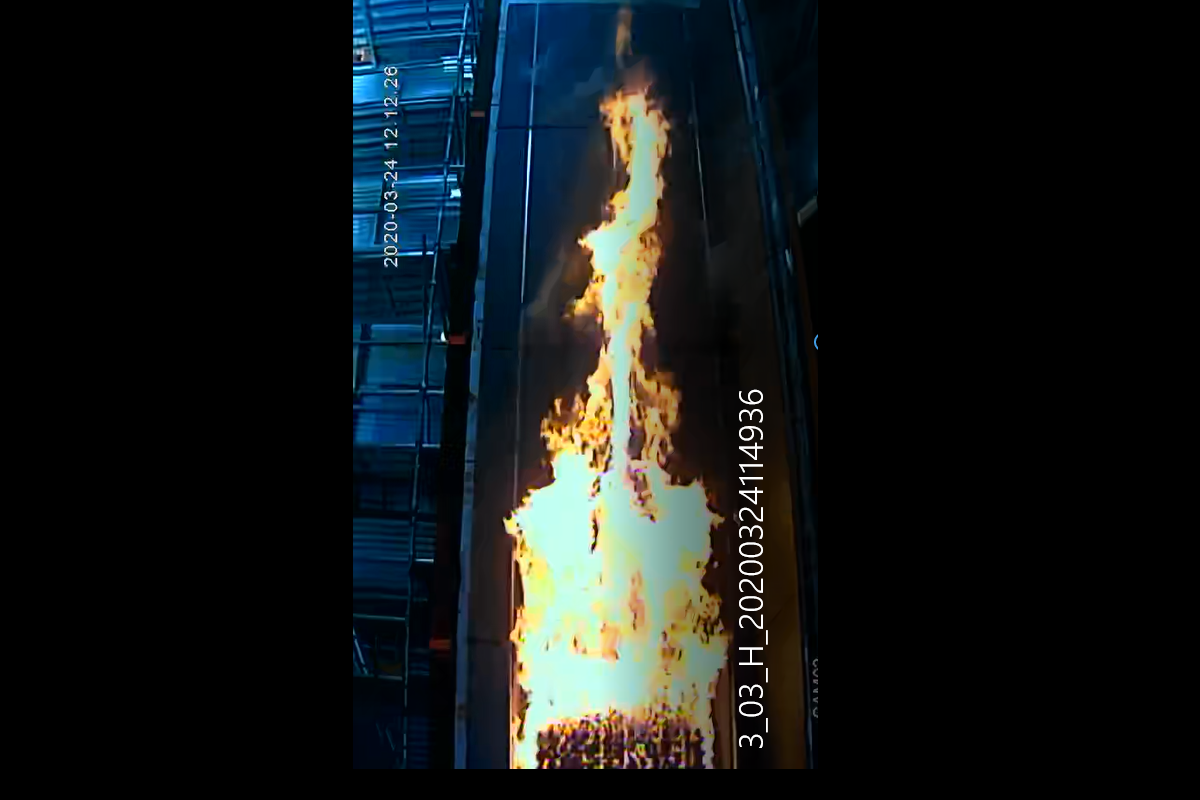

A high-pressure laminate (HPL) cladding system believed to be in use on thousands of buildings has dramatically failed a safety test, with flames ripping through a nine metre test rig in under eight minutes.

It saw a cladding system made of ‘standard grade’ HPL and phenolic foam insulation subjected to a large-scale fire test known as a BS 8414 – the official means of assessing compliance with building regulations.

But the test, paid for by industry body the Metal Cladding and Roofing Manufacturers Association (MCRMA), was halted after just seven minutes and 45 seconds, with temperatures from the huge fire exceeding 700°C.

The result suggests that the system is comparably dangerous to the polyethylene-cored aluminium composite material (ACM) cladding used on Grenfell Tower, which failed the same test in six minutes and 35 seconds in summer 2017.

It also comes just months after a devastating fire at The Cube – a student accommodation block in Bolton – which was seriously damaged when flames ripped through its HPL cladding in November last year.

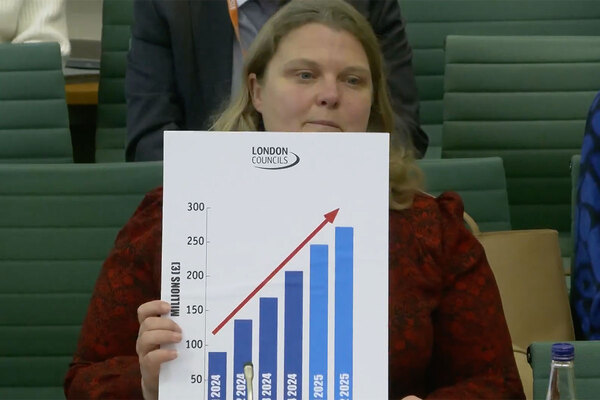

While it has advised building owners to remove standard-grade HPL, the government had refused to fund its removal until the announcement of £1bn of new funding at the Budget earlier this month – claiming that ACM presented a “unique danger”.

It has previously refused to test standard-grade HPL to test this assertion, limiting its testing instead to an HPL product treated with fire retardants, which narrowly passed last year.

In a letter to government, Dr Jonathan Evans, technical committee chair at the MCRMA, said that he had called for the government to test standard-grade HPL in its official programme of testing post Grenfell in 2017, but the government had “flatly refused”.

He arranged the MCRMA-funded test in order to demonstrate the serious danger posed by standard-grade HPL cladding.

“The foundation of [Ministry of Housing, Communities and Local Government’s (MHCLG)] independent expert panel’s advice has been the ‘view’ that [polyethylene-cored] ACM presents a unique danger despite there seemingly being no test evidence to support this. This is not ‘expert advice’ – it is little more than wishful thinking. You can’t hide forever how these materials perform,” Dr Evans wrote.

He added: “From a fire and rescue perspective, the performance of a standard HPL system is practically the same as that of polyethylene-cored ACM – you’ve got just a few minutes to prevent a very serious fire from rapidly developing.

“Arguably, due to the higher fuel content, an HPL fire might be more difficult to fight than ACM due to the greater heat release rate.

“There needs to be a big change in the way fire safety and protection guidance is developed and enforced by MHCLG. Successive secretaries of state have been advised by the same individuals who have presided over the regulatory mess and technical confusion that we now experience and they continue to make serious mistakes and misjudgements that put lives in danger.”

But standard-grade HPL, as used in this test, is thought to be far more common, with some industry estimates suggesting it comprises 85% of the HPL on the market. A estimate of sales show that 300,000 square metres of the material – which comprises wood fibre and resin compressed to form weatherproof boards – were sold every year.

Research by Inside Housing in January revealed that 91 buildings clad with HPL cladding had so far been identified across England, but this was from 1,612 of the 12,000 high rises that are in the country.

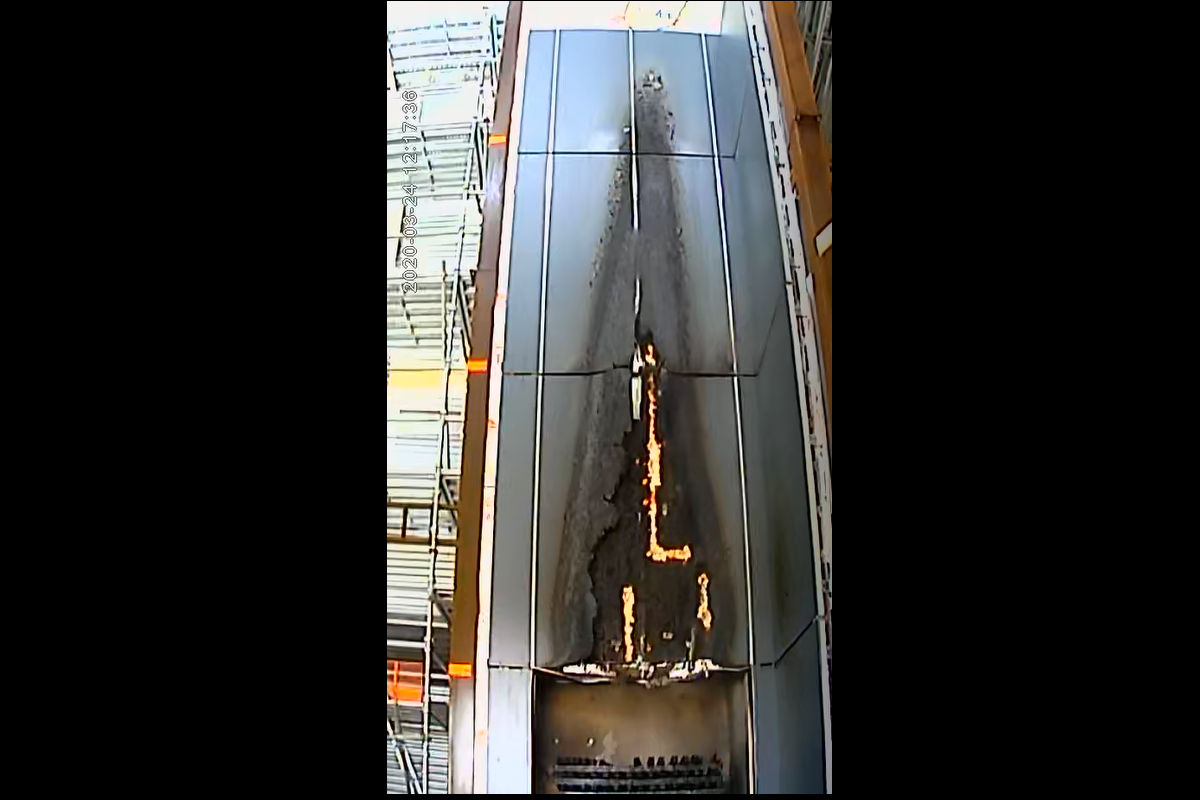

The rig after the test was halted (picture: FPA)

Industry data has suggested there are at least 340 tall buildings with dangerous non-ACM cladding materials – many of which will be HPL. It is also likely to be in use on tens of thousands of blocks below 18m, which still do not qualify for government remediation funding.

Standard-grade HPL window panels caused the external spread of the Lakanal House fire in 2009, which killed six people, including three children.

The test, which involves building a replica wall and lighting a fire in a crib at its base, was carried out at a facility owned by the Fire Protection Authority last week.

The fire spread inconsistently, with the blaze appearing relatively benign before suddenly ripping through the cladding system and causing an urgent termination of the test.

The blaze caused cladding panels to ping out of their rivets, rendering the fire barriers almost useless in slowing the spread of the fire.

One of the technicians was overheard saying “fuck, that’s hot” as the blaze ripped through the panels. The test was halted as flames reached the top of the rig and the fire exceeded the 600°C, which is the pass/fail threshold.

The specific brands of cladding and insulation used in the test have not been released.

An MHCLG spokesperson said: “We have listened to leaseholders and the government has recently announced a £1 billion fund to remediate high-rise buildings with unsafe cladding.

“The department has been clear that external wall systems on high rise buildings using Class C or D High Pressure Laminate (HPL) panels would be unsafe. These materials should not be on any high rise building, and would not comply with regulations.”