Grenfell insulation tested with extra fire-resisting materials, expert report says

Fire-resisting boards were placed between temperature monitors in the now-withdrawn safety test carried out on the insulation used on Grenfell Tower, an expert report submitted to the inquiry has claimed.

Celotex RS5000 insulation passed a Building Research Establishment (BRE) safety test in May 2014, which led its manufacturer to advertise it as suitable for use on tall buildings.

However, this test was withdrawn in January with Celotex admitting “differences between the system as tested and the description of that system in the report of the test”.

In the expert report of Dr Barbara Lane, released by the Grenfell Tower Inquiry last week, it was revealed that these differences included the addition of 6mm magnesium oxide boards to the system tested for fire safety.

Magnesium oxide boards are a commonly used construction product, known for their fire resistance.

“The inclusion of magnesium oxide boards was not shown on the drawings of the system included in the [BRE] report of the test,” Dr Lane’s report said.

She added that the board was “positioned directly between the two layers of thermocouples that determine the pass/fail rating”.

“By placing both boards here specifically the external surface appears to remain more intact during the fire test – thus enhancing the performance of the horizontal open state cavity barriers to operate effectively in the cavity,” she said.

“This could result in the level two thermocouples in the cavity and the level two thermocouples on the outside surface recording a lower temperature, due to the enhanced performance of the cavity barriers.”

In an official test, defined under British Standard 8414 (BS-8414), the insulation system will fail if temperatures rise above 600⁰C for at least 30 seconds within 15 minutes of a fire being lit at the bottom of the system.

Thermocouples are used to measure these temperatures.

Dr Lane’s report also said Celotex is currently unsure whether or not a 10mm gap was included between the panels in the system tested.

This is crucial, she adds, because the lack of a gap could prevent flames entering the cavity and igniting the flammable insulation.

Celotex RS5000, made of a combustible plastic known as polyisocyanurate (PIR), was tested alongside non-flammable cement fibre boards.

Under building regulations, this would have cleared it for use only with this non-flammable cladding and in the specific system installed. However in its marketing the product was described as “acceptable for use in buildings above 18 metres in height”.

Last month BBC Panorama reported that additional fire retardant was added to the insulation before the test in May 2014. Celotex has said it was “unaware of this allegation and had not identified anything which would support it” before Panorama raised it, and has said it “is investigating… as a matter of urgency”.

A repeat of the May 2014 test on RS5000 in April this year saw the product pass.

In its opening statement to the inquiry last week, Celotex said the RS5000 was supplied for use on Grenfell by “third party installers”.

It said a second Celotex product, TB4000, which is also made of PIR was found glued beneath some of the windows on the tower.

“Celotex welcomes the inquiry and, as stated at the outset, is committed to providing its full cooperation and assistance to the investigation,” it said in its opening statement.

The inquiry continues.

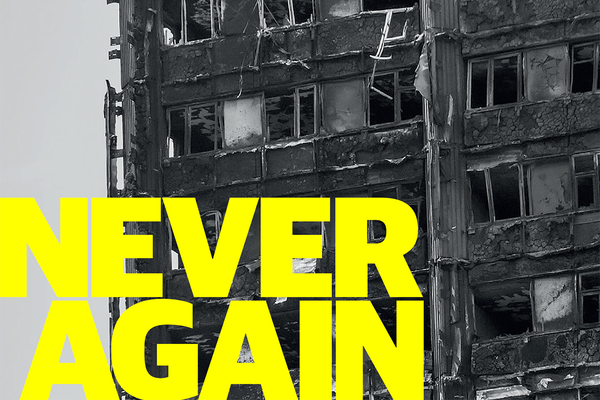

Never Again campaign

Inside Housing has launched a campaign to improve fire safety following the Grenfell Tower fire

Never Again: campaign asks

Inside Housing is calling for immediate action to implement the learning from the Lakanal House fire, and a commitment to act – without delay – on learning from the Grenfell Tower tragedy as it becomes available.

LANDLORDS

- Take immediate action to check cladding and external panels on tower blocks and take prompt, appropriate action to remedy any problems

- Update risk assessments using an appropriate, qualified expert.

- Commit to renewing assessments annually and after major repair or cladding work is carried out

- Review and update evacuation policies and ‘stay put’ advice in light of risk assessments, and communicate clearly to residents

GOVERNMENT

- Provide urgent advice on the installation and upkeep of external insulation

- Update and clarify building regulations immediately – with a commitment to update if additional learning emerges at a later date from the Grenfell inquiry

- Fund the retrofitting of sprinkler systems in all tower blocks across the UK (except where there are specific structural reasons not to do so)

We will submit evidence from our research to the Grenfell public inquiry.

The inquiry should look at why opportunities to implement learning that could have prevented the fire were missed, in order to ensure similar opportunities are acted on in the future.

What are desktop studies, and why are people concerned?

Building regulations say cladding systems which contain combustible insulation must be shown to meet specific standards based on “full scale test data”

A ‘desktop study’ is a means of making an assumption about whether or not a cladding system would meet these standards without actually testing it.

It involves using data from previous tests of the materials in different combinations to make assumptions about how it would perform in a test.

This is not specifically provided for in the current guide to building regulations, but the government believes they are loosely drafted to an extent which makes it permissible. It plans to redraft the guidance to include specific rules on the use of desktop studies for the first time.

The alternatives to a desktop study are full scale testing or not using combustible materials.

People are concerned about the process because it is based on assumption: at least one system cleared through a desktop study has failed a full scale test.

This is important for fire safety because mistakes may mean unsafe cladding systems being cleared for use on tall buildings.