Grenfell insulation product lead admits to ‘reckless optimism’ over ACM pairing

The Celotex employee tasked with leading on the launch of the insulation product installed on Grenfell Tower has admitted to “reckless optimism” over the type of cladding it was suitable for use with.

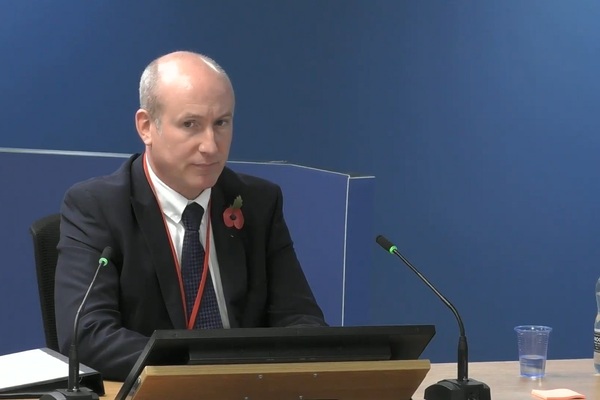

Jonathan Roper, a former product manager at Celotex, was only 23 when he was given the important job of rebranding the company’s FR5000 insulation foam board as RS5000, to compete with rival Kingspan for projects involving buildings taller than 18m.

RS5000, which was launched in August 2014 and installed on Grenfell Tower, was identified as “more likely than not” helping fire spread across the building in the inquiry’s phase one report.

Mr Roper agreed from the witness stand on Thursday that handling the rebrand was a significant personal responsibility for him and admitted: “I was concerned that I knew very little of that marketplace.”

The inquiry heard how he contacted the Building Research Establishment (BRE) in November 2013 to ask about how Kingspan was seemingly able to get its K15 product used in cladding systems which varied from those in which it was tested under Building Regulation 135.

Regulations dictated that products which passed a BS 8414 test under BR135 could only be used on buildings above 18m as part of the same cladding system as that tested.

An email back-and-forth with the BRE ended “without any answers”, Mr Roper told the inquiry.

But Mr Roper went ahead and said in a November 2013 email to Simco, a sub-contractor designing the test rig for Celotex: “As much as they [the BRE] limit the scope of the tested system, they do accept that although one system was tested… they understand that commonly this allows insulation products to be used with a variety of systems in practice.”

Asked if that really reflected advice he had received from the BRE, Mr Roper replied: “Looking at it now, no.”

His email went on to say that carrying out the BS 8414 test with a fibre cement cladding panel product “shouldn’t cause us any issues” with using the RS5000 product behind Reynobond – the type of combustible panel with which it was paired at Grenfell – on other projects.

Under cross-examination, Mr Roper admitted that actually he “didn’t know” this was the case, but that it “seemed the only logical way our competitors were selling into that market into a variety of different cladding systems”.

Referring to evidence heard earlier in the day when a consultant had previously told Mr Roper that RS5000 would not pass the test with an aluminium composite material cladding, inquiry lead counsel Richard Millet QC said: “It was just – forgive me for this – it was just reckless optimism wasn’t it, given what you knew?”

“In hindsight, yes,” Mr Roper responded.

RS5000 would later pass a BS 8414 test – now withdrawn – using fire-resistant boards which were not shown in drawings on the test report.

The Grenfell Tower Inquiry continues.

Sign up for our weekly Grenfell Inquiry newsletter

Each week we send out a newsletter rounding up the key news from the Grenfell Inquiry, along with the headlines from the week

Already have an account? Click here to manage your newsletters