Grenfell cladding sub-contractor did not check drawings for compliance

The owner of the specialist cladding company that installed the deadly system on Grenfell Tower said the firm did not check whether design drawings met statutory requirements and had been “convinced” by the insulation manufacturer that its combustible insulation was suitable for high rises.

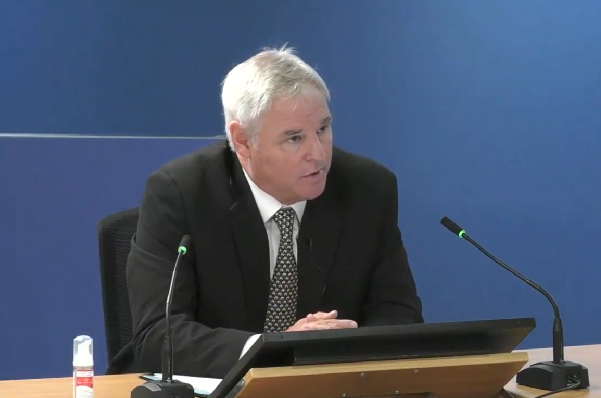

Ray Bailey, founder and managing director of Harley Facades, also told the inquiry today that employees of his firm were not “statutory compliance experts” and that they were reliant on building control inspectors to check that products complied with regulations.

No formal contract was ever signed between Rydon, the lead contractor, and Harley, but it worked under the terms of a ‘letter of intent’ that appeared to make it responsible for ensuring the cladding designs complied with regulations and guidance.

The use of combustible Celotex RS5000 made from a plastic called ‘polyisocyanurate’ was a clear breach of official guidance, which required limited combustibility insulation or evidence from a test of a whole system to justify its use.

Pressed about this, Mr Bailey said: “Celotex made a big, big deal about their product being suitable for buildings above 18m… We not only read the literature we had their technical sales manager in to go through the project, we sent drawings showing the application with the ACM on the building to them and we carried out all possible reasonable [checks].

“And it’s also on the basis that Celotex are produced by Saint Gobain, who are a huge multinational company, and we didn’t believe for a second they would mislead us on this.”

He later added that the firm had “convinced us it complied”.

Celotex is yet to give detailed evidence on its role in the refurbishment, but an opening statement said the “responsibility for the design and construction of the Grenfell Tower refurbishment did not lie with Celotex” and that its “sole role” was as manufacturer and supplier of the insulation.

Asked about why the firm did not raise an issue with designs that did not place cavity barriers above windows – another clear breach of guidance – Mr Bailey said this was not uncommon where there was only one window per flat on the wall.

“Is it right that Harley preceded on the assumption that Studio E had checked the drawings and satisfied themselves that they complied?” Mr Millett asked.

“Yes,” Mr Bailey replied.

“So nobody at Harley checked the drawings for statutory compliance?”

“I think that’s a bit harsh, but yes,” he replied.

He said that any further checks would be done by building control inspectors at the council. Harley did not run any specific checks itself to ensure the materials complied.

“Are you telling us that even though Harley is a specialist contractor with a lot of experience particularly in relation to overcladding high rises you nonetheless relied on building control to check whether the products complied with the statutory requirements?” asked Richard Millett, counsel for the inquiry.

“We are not statutory compliance experts. So when we have a doubt about how something is done we seek guidance and building control are the experts on compliance,” he replied.

In the afternoon session, Mr Bailey was pressed on the selection of Reynobond aluminium composite material panels with a polyethylene core made by multinational company Arconic.

The inquiry heard how he had met with architects from Studio E in September 2013 to discuss the project before being formally appointed.

The firm then produced a budget spreadsheet that indicated the cost of various cladding options, all of them Reynobond.

Mr Bailey said he was only loosely aware that a version of the Reynobond product with a less combustible core was available at a price of only £1 per square metre more expensive.

He said the existence of a certificate from certifier the British Board of Agrement (BBA) confirming both products had a Class 0 rating convinced him they were compliant and in line with requirements in government regulations.

Mr Bailey was shown an email, first released by the inquiry in the first week of evidence, which showed Arconic’s sales manager Deborah French telling its approved fabricators – who cut and sold the product – in 2013 that “we can control and understand what core is being used in all projects due to the controlled supply chain we have”.

The email was in relation to fires involving ACM in the Middle East, and Mr Bailey said he was “shocked” to read it. “None of that has been fed down to us,” he said.

He earlier insisted he had no knowledge of these fires, despite coverage in the British media.

Mr Bailey also explained that the company which originally took on the work, Harley Curtain Wall, went into administration in September 2015 before the completion of the project. The work was passed over to a dormant company also owned by Mr Bailey called Harley Facades.

The inquiry continues with more evidence from Mr Bailey tomorrow.

Sign up for our weekly Grenfell Inquiry newsletter

Each week we send out a newsletter rounding up the key news from the Grenfell Inquiry, along with the headlines from the week

Already have an account? Click here to manage your newsletters