BBA published ‘materially wrong’ certificate on Grenfell cladding after manufacturer ‘stonewalled’ data requests

The British Board of Agrément (BBA) published a “materially wrong” certificate covering the cladding material later used on Grenfell Tower, after its manufacturer “stonewalled” requests for information for 16 months.

Valentina Amoroso, former project manager at the BBA, today accepted that an updated certificate published in 2015 lacked crucial test data, after she elected to conduct her review from publicly available sources, having been unable to obtain information from manufacturer Arconic.

She was unaware that Arconic had conducted fresh testing and that its panels gained a far lower fire classification than the one they were given after the 2005 test, which the certificate was based on.

The BBA – the UK construction sector’s most trusted certifying body – had originally issued a certificate for Arconic’s Reynobond 55 cladding panels in 2007. This said the material “may be regarded” as Class 0 – the required standard for high rises under English guidance at the time.

But Arconic had tests dating back to 2005 showing that the panel would perform disastrously in a fire if it was bent and hung onto a building on rails (known as a ‘cassette’ system) as opposed to being bolted to the walls (a riveted system).

This was confirmed with further testing in 2011 and 2014, but was not shared with the BBA until the tests were uncovered by a BBC journalist after the Grenfell Tower fire. The cladding used on Grenfell Tower was bent into cassette form.

The certificate was due for review in January 2014 and Ms Amoroso’s predecessor at the BBA first contacted Arconic’s management requesting the necessary material in October 2013.

But she received no response to this or seven further emails stretching through to May 2014, when Claude Wehrle, a senior member of Arconic’s technical team, finally responded.

She sent him a list of required information, including any “details that would invalidate the certificate”.

Responsibility for completing the review was then handed over to Ms Amoroso in November 2014, three months after she joined the company, with the information from Arconic still outstanding.

She continued to chase throughout January, getting no response other than contact details of other people to speak to.

“Did you get the impression they were stonewalling you?” asked inquiry counsel Richard Millett QC.

“Perhaps,” Ms Amoroso replied.

Finally on 22 January 2015, she emailed Arconic to say that the BBA had “decided to go ahead with the material in hand”. She said this was a reference to the existing information the BBA had, along with publicly available material on Arconic’s website.

“Did it not occur to you that Arconic, by not answering repeated requests for so long, were up to something?” Mr Millett asked.

Ms Amoroso said it was “not unusual” for certificate holders not to engage in a review process. She said she would only have expected to receive additional testing data if Arconic had changed the way it manufactured the product, and she had no reason to suspect it did.

Pressed by Sir Martin Moore-Bick, chair of the inquiry, on why she did not simply refuse to offer a reviewed certificate without the requested information, she said it was not the BBA’s policy to do so unless the certificate-holder was refusing access to factories for inspection visits.

By the time the updated certificate was issued in April 2015, fresh Arconic testing had shown that its cladding panels obtained a European ‘C’ grade for fire when fixed to a wall with rivets and an ‘E’ grade when bent into cassettes.

But the certificate reached its conclusion that the product “may be regarded” as Class 0 in part on the basis of earlier testing that resulted in it being given a ‘B’ grade when riveted to the wall.

“Do you agree that this [new] testing meant the certificate had become materially wrong?” asked Mr Millett.

“Yes,” Ms Amoroso replied.

“When a reader looked at it they would have been entitled to think that the BBA had satisfied itself that the claims about fire performance were true, wouldn’t they?” asked Mr Millett.

“Yes,” replied Ms Amoroso.

The inquiry was shown an internal BBA email from Ms Amoroso’s line manager that referred to her team dropping down “the ‘closed reviews’ leader board”.

Ms Amoroso said this was meant as a joke, but did say there was pressure to close reviews before the end of the financial year in March.

The BBA certificate was provided to the team refurbishing Grenfell Tower by Arconic’s sales representative on 23 April 2014.

This afternoon, the inquiry heard about a later scheduled review of Arconic’s Reynobond 55 cladding panels that Ms Amoroso began carrying out in 2016.

During this review, Ms Amoroso was told by Arconic that the company did not manufacture the cassettes and therefore took “no responsibility” for it.

This led Ms Amoroso to conclude that the BBA’s certificate should not cover Reynobond 55 when attached in cassette form.

Ms Amoroso said the cassette system – which was shown in a diagram in the certificate – “should not have been part of the certificate in the first place”.

“Given that you realised that the certificate had covered cassettes for some eight or nine years on an erroneous basis, did you raise that fact with anybody more senior to you at the BBA?” asked Mr Millett.

“That was part of me raising the fact that there hadn’t been any BBA surveillance in the previous years,” Ms Amoroso replied.

Following Ms Amoroso’s review, the BBA issued a new certificate for Reynobond 55 in August 2017, after the fire at Grenfell.

Again, this certificate contained no reference to the tests that showed a lower fire performance for the product to the one mentioned in the certificate, as Ms Amoroso was still unaware of these tests.

Ms Amoroso told the inquiry that the BBA had not asked Arconic for additional testing on its product after the fire at Grenfell as it was not “common procedure”.

Mr Millett asked: “Why not? There had been a fatal fire only a few weeks before. My question is why didn’t you insist or anybody else at the BBA insist on either seeing Arconic’s up-to-date fire tests for both PE and FR, or at least insist on a confirmation that you had all relevant and up-to-date test data in your hands?”

“That is not a question for me. I was just doing what I was asked to do at the time,” Ms Amoroso replied.

The inquiry learned that the BBA did not find out about the additional tests carried out by Arconic until it was contacted about them by BBC journalist Tom Symonds in 2018.

Mr Millet said: “Can you account for how it was left to a BBC journalist to uncover these facts and that the BBA had for so many years failed to do so?”

Ms Amoroso said that she “cannot account for that” and that she believed the “BBA’s procedures should have been different”.

The inquiry continues.

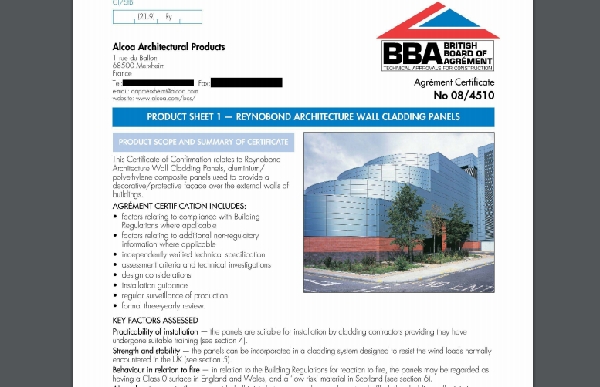

What did the BBA certificate say?

The BBA certificate is a crucial document in understanding why the highly combustible cladding panels were used on Grenfell Tower.

It was provided to the team that refurbished the building, and several witnesses have said it assured them the panels had a ‘Class 0’ rating – meaning they could be used on a high rise.

The certificate said the Reynobond 55 cladding panels – available with either a polyethylene or fire-retardant core – “may be regarded as having a Class 0 surface”.

It said this was based on two European tests in which both the polyethylene-cored and fire-retardant panels had obtained a ‘Class B’ rating, and tests to English standards on the fire-retardant version only, which had resulted in a ‘Class 0’ rating. Taken together, the BBA concluded that these results meant both the polyethylene and fire-retardant products could be considered Class 0.

But both the European tests were on cladding panels fixed to a wall with rivets. When tested in the other possible means of fixing them (bending them into cassettes and hanging them from rails) they had burned catastrophically and achieved a Class E. Arconic did not share this test result with the BBA despite it having been carried out three years before the certificate was issued.

The BBA certificate did not make it clear that European tests had been carried out only on the riveted panels, despite containing a diagram showing both rivet and cassette fixings.

It also said that the tests had been carried out on grey/green and gold-coloured panels, and specifically noted that other colours may not achieve the same rating. The panels used on Grenfell Tower were smoke silver.

Sign up for our weekly Grenfell Inquiry newsletter

Each week we send out a newsletter rounding up the key news from the Grenfell Inquiry, along with the headlines from the week

Already have an account? Click here to manage your newsletters