Grenfell Tower refurbishment: a timeline

Following the conclusion of module one of the Grenfell Inquiry’s second phase, Peter Apps presents a timeline of the key moments during the fatal refurbishment of the west London tower block. Pictures by Grenfell Tower Inquiry

Above: Grenfell during its refurbishment in 2015

Module one of the Grenfell Tower Inquiry looked at the details of its refurbishment – the work that was done to the tower, who did it and why. The second module, which began on 5 November, looks at the actions of the companies which manufactured and tested the products used in the cladding system.

Here, we sketch out what has been uncovered about the deadly refurbishment of the London tower.

1 November 2011

Amid plans to build a school and leisure centre at the base of Grenfell Tower, the Royal Borough of Kensington and Chelsea (RBKC) and building manager Kensington and Chelsea Tenant Management Organisation (KCTMO) discuss plans to refurbish the tower as well. An email sent on this day reads: “The TMO is also keen to investigate the opportunity to clad Grenfell Tower… This will… prevent it looking like a poor cousin to the brand-new facility being developed next door.”

29 February 2012

The architect designing the school, Studio E, is asked to carry out work on the tower as well. Studio E has no experience of high-rise work but the fee is split, meaning no competitive procurement is ever carried out. Leadbitter, the contractor working on the school, is also appointed to work on the tower.

4 April 2012

Bruce Sounes, the lead architect at Studio E, selects a solid zinc panel as his preferred choice for the cladding system. But at a meeting with fabricator CEP Architectural Facades, the firm’s sales director suggests a cheaper option: aluminium composite material (ACM).

16 August 2012

Consultant Max Fordham emails Studio E to say it has found a product that can meet the “aspirational” insulation target. “I think this is the only type of product that will give us the required performance,” writes engineer Andrew McQuatt. The product is made of combustible plastic and does not meet basic standards in building guidance. Neither knew this.

31 October 2012

Fire safety consultant Exova produces its first fire strategy for the refurbishment plans. This makes no mention of plans to clad the building and says the work is expected to have “no adverse effect on the building in relation to external fire spread, but this will be confirmed by an analysis in a future issue of this report”.

26 February 2013

The estimate of the cost of the project made by Artelia, a consultant acting for KCTMO, is around £2m higher than the estimate made by contractor Leadbitter and the project grinds to a standstill as the team hunts for savings. Mr Sounes is told to carry out a “radical rethink of the scope/spec… to deliver it within budget”. He replies with “zinc cladding to something cheaper” as listed as a potential option.

April 2013

Artelia writes a status report on the project, advising that “the project is currently over budget with little expectation that… costs will be aligned or reduced sufficiently to make the scheme affordable”. It predicts that “unless… a fundamental review is embarked upon to redefine the scope, programme and cost, it will fail”.

21 May 2013

At a meeting between KCTMO and RBKC, it is decided that “value for money is to be regarded as the key driver for the project”. The Artelia report is altered to recommend reprocuring for a new contractor to do

the works more cheaply.

Grenfell Tower after the refurbishment

27 September 2013

Mr Sounes meets representatives of cladding subcontractor Harley Facades at a coffee shop. “They said their recurring experience is that budgets force clients to adopt the cheapest cladding option: ACM,” Mr Sounes writes in an email following the meeting. Harley goes on to investigate the costs of several cladding products for Mr Sounes, but tells him: “From a Harley selfish point of view, our preference would be to use ACM.”

5 November 2013

Exova produces what will be the final version of its fire strategy. It still contains no reference to the cladding plans and says the designs will have “no adverse effect” in relation to external fire spread, but that this will be confirmed by a future analysis.

21 November 2013

Studio E prepares a specification for the job, to enable potential contractors to price their bids. This document lists Celotex as the insulation material and a solid zinc and aluminium panel made by Proteus for the cladding. But it also lists a Reynobond ACM product as one of three potential alternative cladding panels.

6 March 2014

Three contractors have submitted tender bids: Mulalley quotes £10.48m, Durkan £9.94m and Rydon £9.249m, which puts Rydon in the lead. Internal Rydon emails note it had a meeting with KCTMO officials at a housing conference in Brighton. “We have been informally advised that we are in pole position – ours to lose,” one email states.

18 March 2014

Ahead of the formal award of the contract, KCTMO has an “offline” meeting with Rydon about further reducing the cost of the job to meet the £8.5m budget – including making savings by switching the cladding panel for a cheaper option, despite legal advice that conversations of this nature were prohibited before the contract was awarded. To cover a £200,000 estimating error in its own bid, Rydon understates the potential savings.

31 March 2014

Rydon is formally notified that it is the successful contractor to design and build the refurbishment. Studio E would be selected to continue its work and Harley would formally join the team as the cladding subcontractor.

8 May 2014

The design team seeks permission from the planning department at RBKC to switch the zinc cladding to ACM. A certificate from the British Board of Agrement is circulated among the team that suggests the panels have a Class 0 fire rating – which the team takes to mean it complies with building regulations. None read it in detail. The planners eventually approve the switch but insist on the use of ‘cassette’ cladding panels – which are hung on to the tower using hidden rails. These – it later emerges – have a far worse fire performance.

June 2014

A mock-up of the cladding is installed on Grenfell Tower. This uses cladding panels with a fire retardant core – the eventual cladding will be the far more combustible polyethylene.

CGI image of planned refurbishment, showing cladding and school nearby

4 August 2014

An application is made to building control for ‘full plans approval’ – confirmation that the planned work complies with building regulations. Supporting drawings are not submitted until 24 September and they are out of date – with the cladding material still marked as zinc.

18 September 2014

Neil Crawford, an architect working for Studio E, emails Terry Ashton at Exova with drawings produced by Harley to ask for guidance on the correct positioning on cavity barriers. Exova was not appointed by Rydon, but Mr Crawford does not know this. He advises that “if the insulation… is combustible you will need to provide cavity barrier as shown on your drawing”. This advice is wrong – combustible insulation should not have been used and the drawing missed them in key locations, such as around windows.

12 November 2014

Clare Williams, project manager at KCTMO, emails first Artelia and then Rydon querying the “flame retardance [sic]” of the planned cladding. “I just had a ‘Lacknall’ [sic] moment,” she says in reference to the Lakanal House fire in Southwark in 2009 – where combustible window panels helped a fire spread up the exterior of a building. There is no record of any reply from Rydon.

18 November 2014

Building control officer John Hoban emails Studio E, saying he is giving full plans approval to the project. He says this was issued subject to conditions, but no record of these conditions has ever been found.

17 March 2015

Ben Bailey, the 25-year-old son of Ray Bailey, the managing director of Harley Facades, purchases the Celotex insulation from third-party supplier SIG at a 47.5% discount. It will be one of the first tall buildings to use Celotex and the firm will later enquire about the possibility of using it as a case study.

27 March 2015

Amid a debate with building control over whether or not ‘fire stopping’ was required in the cladding system, Daniel Anketell-Jones, a designer with Harley Facades, emails saying: “There is no point in ‘fire stopping’, as we all know; the ACM will be gone rather quickly in a fire!” He explains that he was referring to solid metal cladding detaching from the building and falling off – not the rapid fire spread seen at Grenfell Tower.

30 March 2015

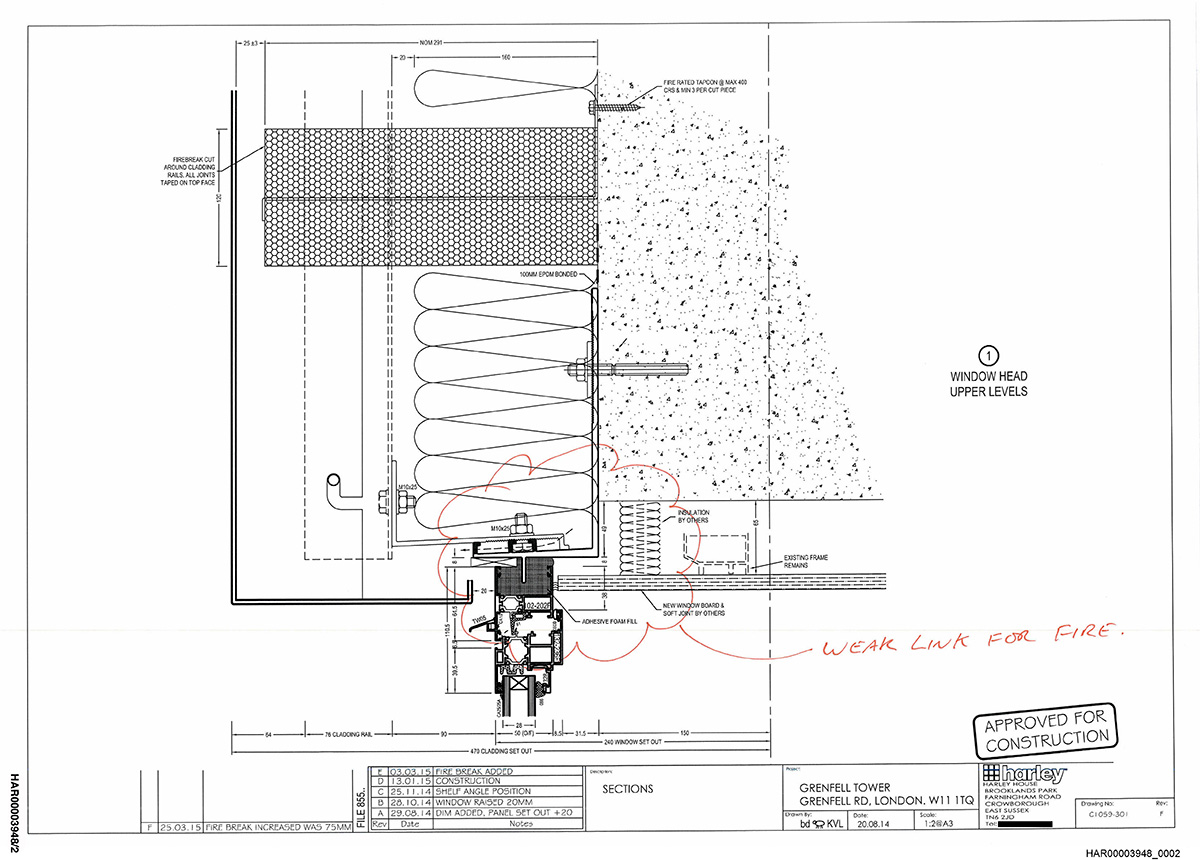

Siderise, the subcontractor that sold the cavity barriers, emails design drawings to Ben Bailey highlighting an area at the top of the windows and calling it a “weak link for fire”. He suggests moving the cavity barrier down to close this gap. Mr Bailey does not forward this email on.

6 May 2015

Emails show combustible Celotex insulation has been selected by the team on site to fill gaps around the new windows, despite the specification listing non-combustible Rockwool as the required product.

Drawings annotated by Harley note ‘weak link for fire’

26 May 2015

Informed that SIG is running temporarily low on Celotex, Ben Bailey orders a quantity of Kingspan K15 as a substitute. The client, KCTMO, is never informed about the switch.

22 June 2015

With work progressing slowly, Rydon manager Simon Lawrence writes: “At the moment we have a poorly performing site which is mainly (but not totally) caused by poor surveying and cheap incompetent subcontractors.” Over the course of the next year, inspections on the cladding work will be carried out by building control, the clerk of works, site managers for Rydon and Harley, and the subcontractor that installed it – Osborne Berry. None will turn up the major flaws of the installation, which include cavity barriers installed upside down and vertical barriers installed horizontally or missing entirely.

29 July 2015

A report by the clerk of works notes there are only seven workmen on site working on the cladding. The project is delayed and behind schedule for its target finish date in October.

27 October 2015

Changing regulations relating to record-keeping mean KCTMO is taking over as ‘principal designer’. This requires a handover of key information from Artelia – including a health and safety file, which should contain details of the construction of the building and its safety. Gathering this information is a legal requirement but this has only been partially completed and is never fully done.

9 May 2016

With the project severely overrunning its projected finish date, Neil Reed, a consultant at Artelia, writes to Rydon to say: “This is becoming a farce; despite all our efforts to ensure a smooth landing I have to say I do not think I have ever worked with a contractor operating with this level of nonchalance.”

13 May 2016

A KCTMO press release celebrates the completion of the refurbishment. “It is remarkable to see first hand how the cladding has lifted the external appearance of the tower,” says council leader Nicholas Paget-Brown.

7 July 2016

RBKC building control issues a completion certificate for the project.

Sign up for our fire safety newsletter

Already have an account? Click here to manage your newsletters